Laminating rollers

Laminating rollers, standard rollers, radius rollers, paddle wheel rollers, Bubble Buster rollers, Corner rollers, flex rollers, bristle rollers, steel star rollers.

Step 1. Select roller head style

First choose the head style of the laminating roller you want. Then you will be able to select a frame option available for that head style. Finally you will be able to choose additional options such as an aluminum or plastic roller head, a wood or plastic handle grip, and which manufacturers' roller you prefer. Start here by choosing the head.

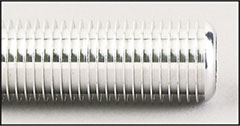

Standard rollers

Standard rollers are available with aluminum or plastic heads. This is the original vertical fin design. Larger sizes are mostly parallel thin fins and deep grooves. Some smaller sizes have shallow angled fins. Fins on a few of the plastic economy rollers are spiral wound. Start here if the laminating roller you want has a standard aluminum or plastic head.

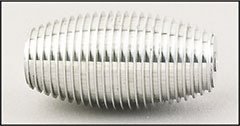

Radius rollers

Radius rollers are available with aluminum or plastic heads. These are barrel shaped heads with vertical fins. Shape of head matches a specific radius of a circle, like pipe or other concave surfaces. Radius is one half of the diameter. Also used when a straight standard head won’t insure bonding on uneven surfaces. Start here if the laminating roller you want has a barrel shaped head.

Paddle wheel rollers

Paddle wheel rollers are available with aluminum heads. Regular paddle wheel has horizontal fins running down the length of head. Slotted paddle wheel head is a variation of this style with cross-cut fins. This provides more air release in heavily filled resins. Often preferred when working with knitted/unidirectional fabrics. Start here if the laminating roller you want has either of these paddle wheel designs.

Bristle rollers

Bristle rollers are pure hog bristle that is spiral wound onto quick-change frames. These rollers provide good air release and work well releasing air trapped under uni-directional mat. These laminating rollers are also used for skin coats and mold construction. Bristle rollers are easy to clean because they flex.

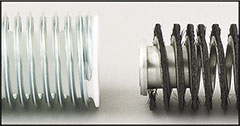

Flexible rollers

Flexible rollers are available in two different styles: flexible steel and flexible bristle. Both are contour laminating rollers that flex to roll out various convex or concave surfaces. The flexible steel roller is a spring steel design. Flexible bristle rollers are a spiral wound flexible bristle. These flexible bristle rollers are larger than the regular bristle rollers listed below. Replacement parts are available for the flexible bristle rollers.

Bubble Buster rollers

Bubble Buster rollers are available in the original Bubble Buster design with aluminum or plastic heads that help deflate air pockets in hard to reach areas away from the edge of the laminate.

Corner rollers

Corner rollers or fillet rollers match a specific inside corner radius. Heads are aluminum, plastic, or bristle. Deep fins in the aluminum and plastic heads allow quick air release. Bristle heads are good for irregular fillets. Start here if you're looking for this type of laminating roller.

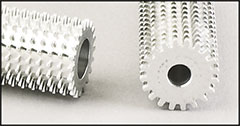

Steel star rollers

Steel star rollers are made with heat treated steel stars and washers that won't pick up the glass, but will roll it out smoothly. Works well on large surfaces. When using extension handles, less pressure is needed because of the weight of these laminating rollers. Cleans easily in solvent.